Cisa Group develops disinfection and washing technologies for all operational needs, in line with current regulations and the different production capacities of hospitals, clinics and medical facilities of all sizes.

Cisa Healthcare’s washing and washer-disinfection systems are used inside hospital CSSDs in the automatic high-temperature washing stages to process medical devices that, according to sterilisation regulations and procedures, require thermal disinfection.

They can thermally process medical devices and surgical instruments used in hospital and healthcare settings and subject to chemical washing and drying other items normally used in healthcare, in compliance with current standards.

Within the hospital CSSD, Cisa Healthcare washer-disinfectors are positioned between the dirty and clean areas.

A first, important step in the sterilisation process for hospital infection control.

The washing and disinfection of surgical instruments, reusable medical devices (RMDs) and anaesthesia accessories used in operating theatres is a necessary pre-treatment stage prior to sterilisation in autoclave.

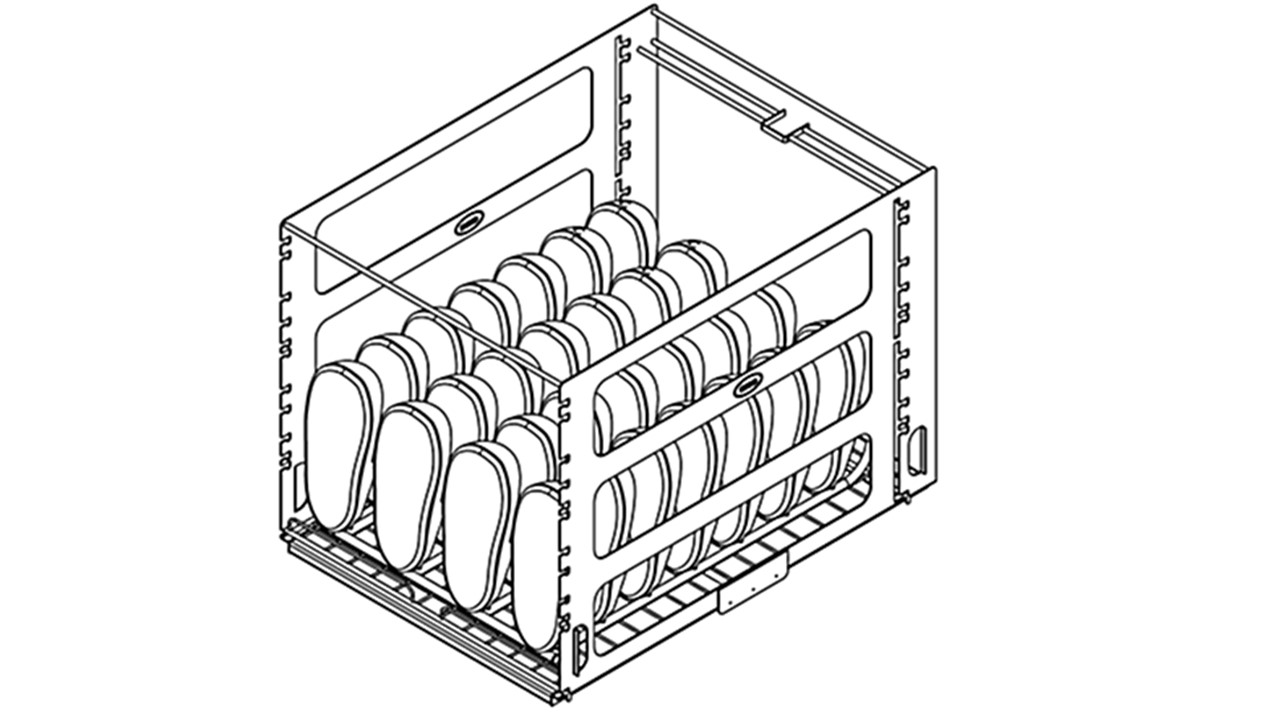

Other work instruments as well, such as RMDs, staff clogs and shoes, surgical equipment and containers that do not undergo the sterilisation process are generally subject to the chemical washing and disinfection stage.

The range includes small and compact technologies for healthcare applications with lower productivity or large equipment to finalise hospital and CSSD projects with high production capacities.

*DIN tray = 480x250x50H mm

Underbench washing

and disinfection systems

6 DIN - 106 L

Medium-sized washing

and disinfection systems

12 DIN - 225 L

Large washing

and disinfection systems

18 DIN - 400 L

36 DIN - 800 L

Compact, high-capacity

trolley washers for beds br>and operating tables

2790 -5250- 5580 L

Underbench washing and disinfection system

Compact, under-counter washer-disinfector, ideal for small spaces. With a treatment capacity of up to 6 DIN, it is the thermal washing and disinfection solution designed for laboratories, medical centres and dental practices.

Medium-sized washing and disinfection systems

A freestanding washer-disinfector with a compact design and small footprint that meets small and medium production needs with high-performance washing and drying results.

Even in its standard version, the CISA P-M104 shows high levels of efficiency for its category, ensuring that only 6.7 litres of water in total are consumed for the thermal disinfection of each DIN, one of the lowest values compared to the market average.

Available in single door or double door versions.

The shape and volume of the washing chamber, made entirely of AISI 316L stainless steel, are designed for loading multi-purpose baskets and trolleys and modular trays up to 12 DINs.

Freestanding washer-disinfectors with FAST System

for high-performance reprocessing of RMDs.

Capacity and power for the productivity of large hospital CSSDs. Even starting with the 2F version, it can guarantee a water consumption of only 6 litres for the thermal disinfection of each DIN, one of the lowest values on the market, and an improvement on the already high-performance CISA P-M 104. In the 3F configuration this saves an additional 25% of water.

Even the 2F has cycle times of less than 30 minutes including drying.

Available in both single door or double door version. Washing chamber in AISI 316L stainless steel, with shape and volume to allow the loading of trays, baskets and multi-purpose and modular trolleys up to 18 DIN.

Freestanding washer-disinfector with dual-capacity FAST System.

This is Cisa’s solution for the most modern, highly automated hospital CSSDs.

Available in single door or double door versions.

The shape and volume of the washing chamber allow for the loading of trays, baskets and multi-purpose and modular trolleys up to 36 DIN.

Large system with high flexibility

One of the narrowest freestanding washer-disinfectors on the market, it allows the most complicated configurations to be made highly performing. Specific options and accessories for higher efficiency and lower consumption.

Available in single door or double door version. The shape and volume of the washing chamber allow the loading of trays, baskets and multi-purpose and modular trolleys up to 18 DIN.

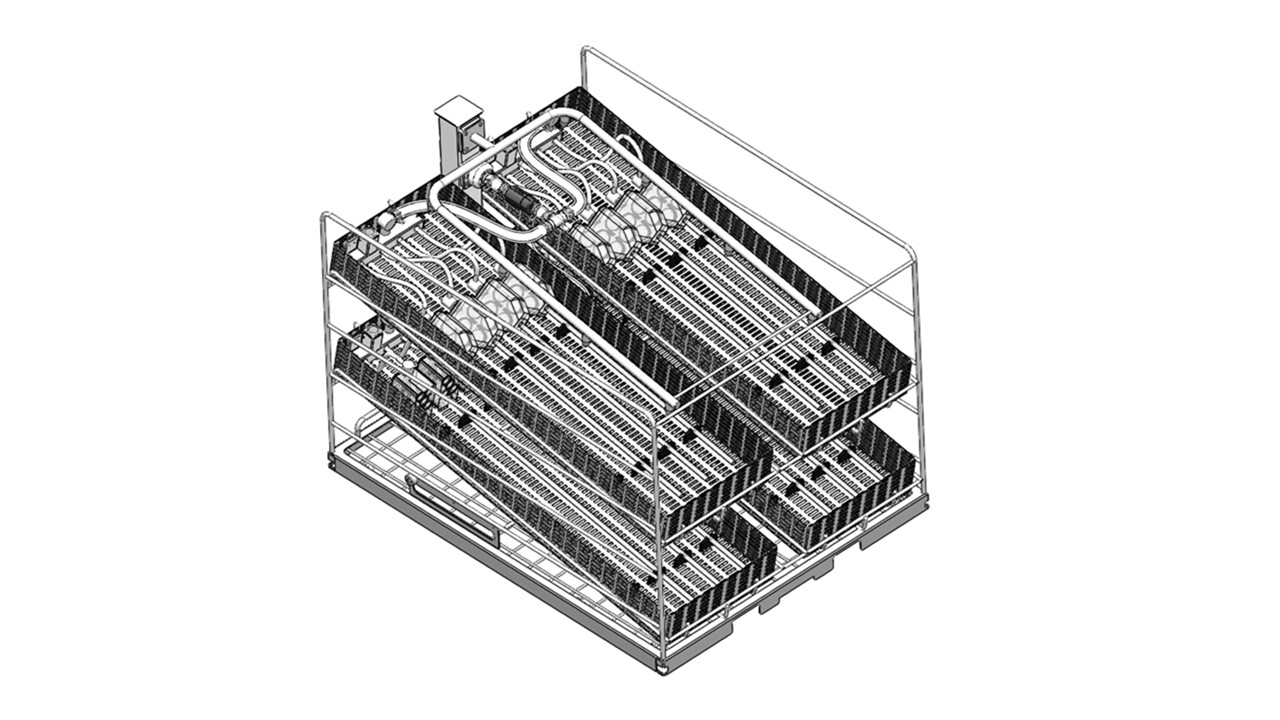

Trolley and container washing system

Ideal for treating containers, wash basins and collecting containers as well as bulky items such as trolleys.

Compact design with technical module adjacent to the chamber. Can be installed above floor level with suitable external ramps or at floor level, for which an only 120 mm deep pit is required, thereby providing an easy installation solution even in complex projects and sites.

Automatic horizontal sliding door. Large, 1500mm deep AISI 316L stainless steel washing chamber.

Double capacity system for washing trolleys and containers

Ideal for washing and thermal disinfection of containers, wash basins and collecting containers as well as bulky items such as trolleys.

Compact design with technical module adjacent to the chamber. Can be installed at floor level for loading without the aid of ramps or off the floor, with suitable external ramps. Automatic horizontal sliding door. Double washing chamber in AISI 316L stainless steel with a depth of 3100 mm for enhanced productivity.

Washing system for hospital beds and operating tables

Ideal for reprocessing hospital beds and other bulky items such as operating tables. It can be manufactured in both medical and non-medical device versions, representing the best compromise in terms of flexibility of use. It features a compact design with a technical module adjacent to the chamber. Can be installed at floor level and above floor level according to design requirements. Double glazed tempered glass door with automatic horizontal sliding. Washing chamber in AISI 316L stainless steel, with a depth of 2500 mm.

The P-KF series of trolley washers can be configured in 3 different solutions by implementing the Fast System and Eco System, which are ideal for reducing the passive loading and water heating times, thus resulting in a shorter total cycle time. The Eco System 3F option also allows to effectively save 27 litres of demineralised water per cycle.

FAST System 1F

Up to -10 cycle minutes = speed

FAST System 2F

Up to -20 cycle minutes

Up to -20 cycle minutes and at least -27 litres of demineralised water per cycle.

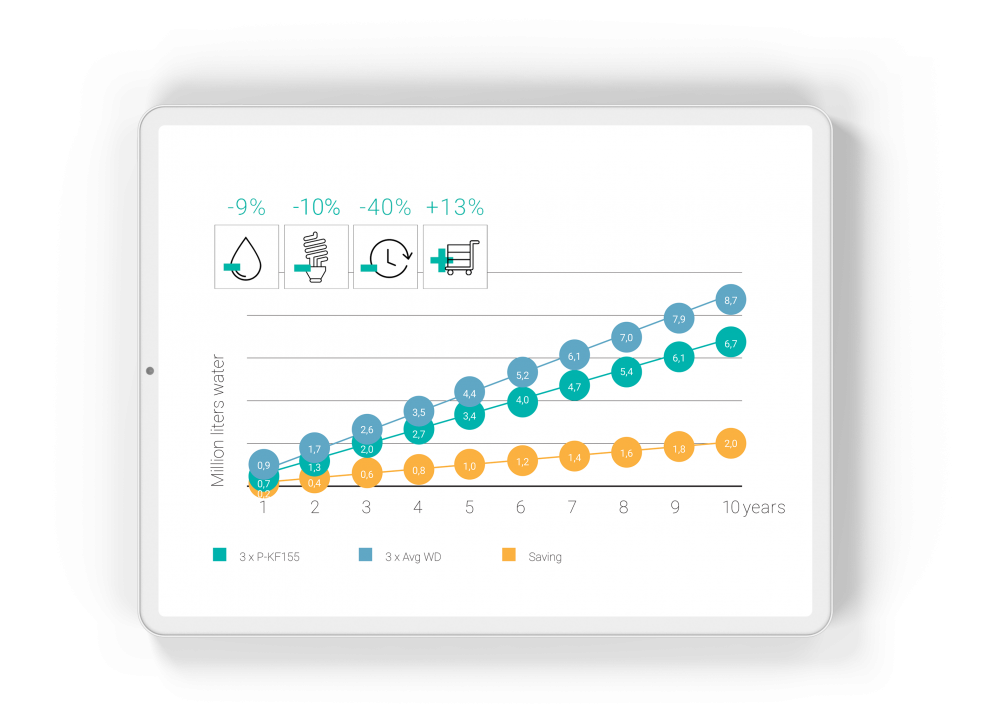

A production capacity almost 13%** higher than similar technologies on the market and a reduction in consumption that records up to 9% less water per cycle (and related consumables), for a total saving of over 23,000 liters of water per year, over 2 million liters in 10 years, with a reduction in electricity consumption of 10%.

recovery of part of the water for subsequent washings with a considerable consumption saving on each cycle

lower thermal and electrical power for water heating, and heat recovery and containment systems

for water heating, up to - 20 minutes per cycle

up to 342 DIN/trays 8h/day**

1 |

1Lasting qualityAISI 316L stainless steel with highly corrosion-resistant mirror finish inside. |

2Process effectivenessFlexible loading capacity, optimal washing and drying in compliance with regulations and without increased space requirements in all versions |

3Reduced timesHigh-flow water pump and technical features designed for proven savings. |

4Operators’ and process safetyHigh levels of safety and multi-level alarms with simple and clear notifications. |

5Ergonomic designLED colour indicators, intuitive control panel, touch-screen comfort and useful loading accessories |

6Automatic processAutomatic loading and unloading, automatic trolley and load recognition, automatic cycle start. |

7Chemical validationValidated chemical pre-configuration and central dosing for multiple machines. |

8Configurable optionsMaximum customisation according to industry type, operational needs and site requirements |

9Easy maintenanceFront access to equipment; integrated technical guides and maintenance programmes, remote maintenance. |

10Traceability systemLink to proprietary TraceCare® software for process control and cycle validation. |

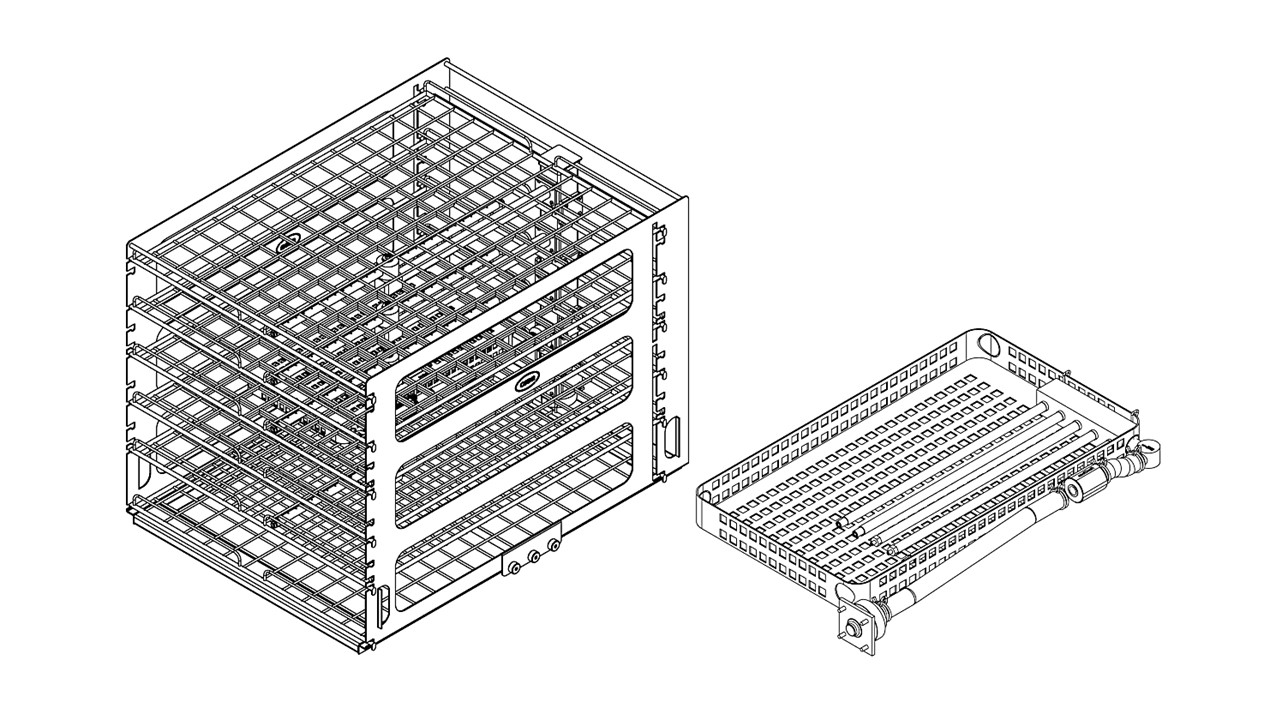

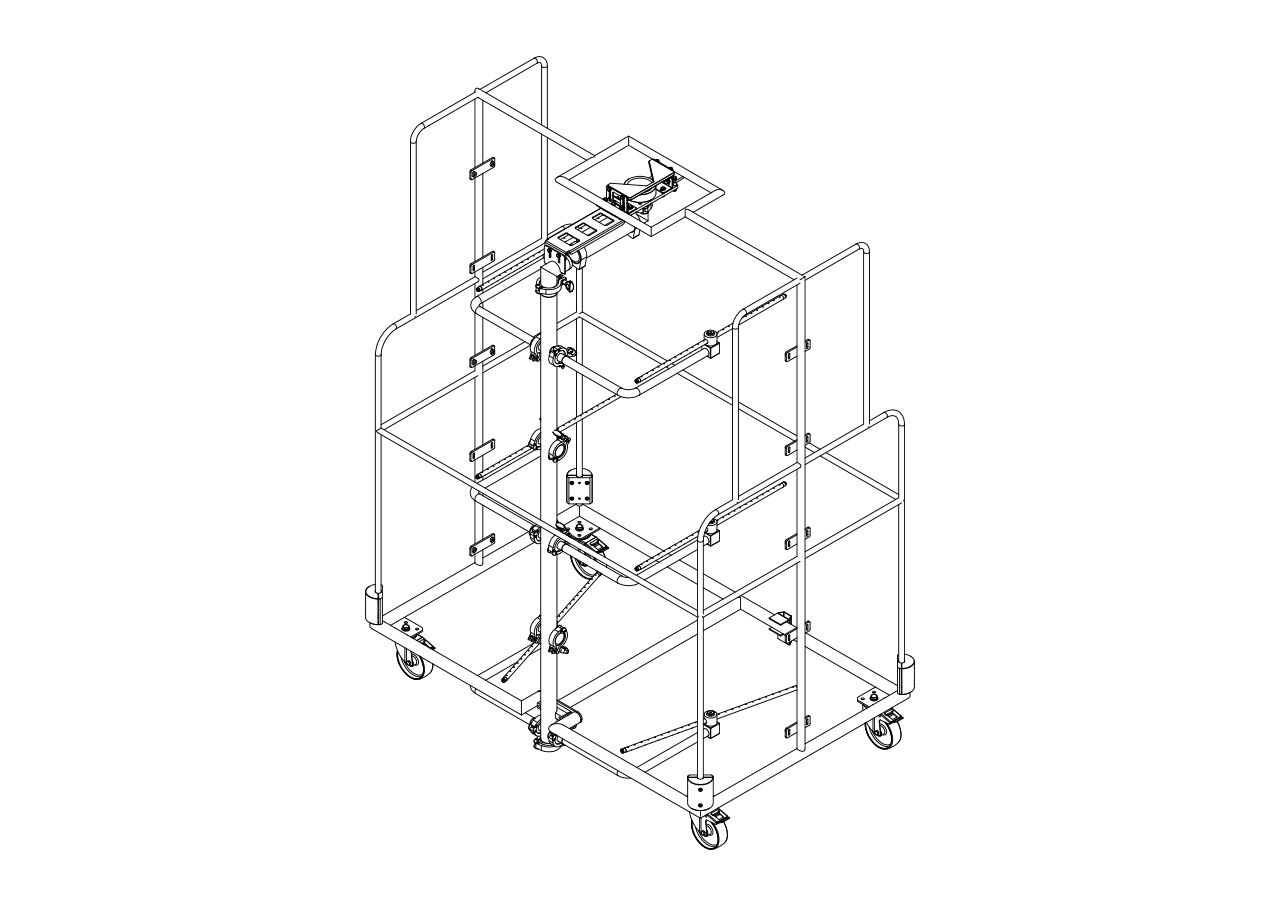

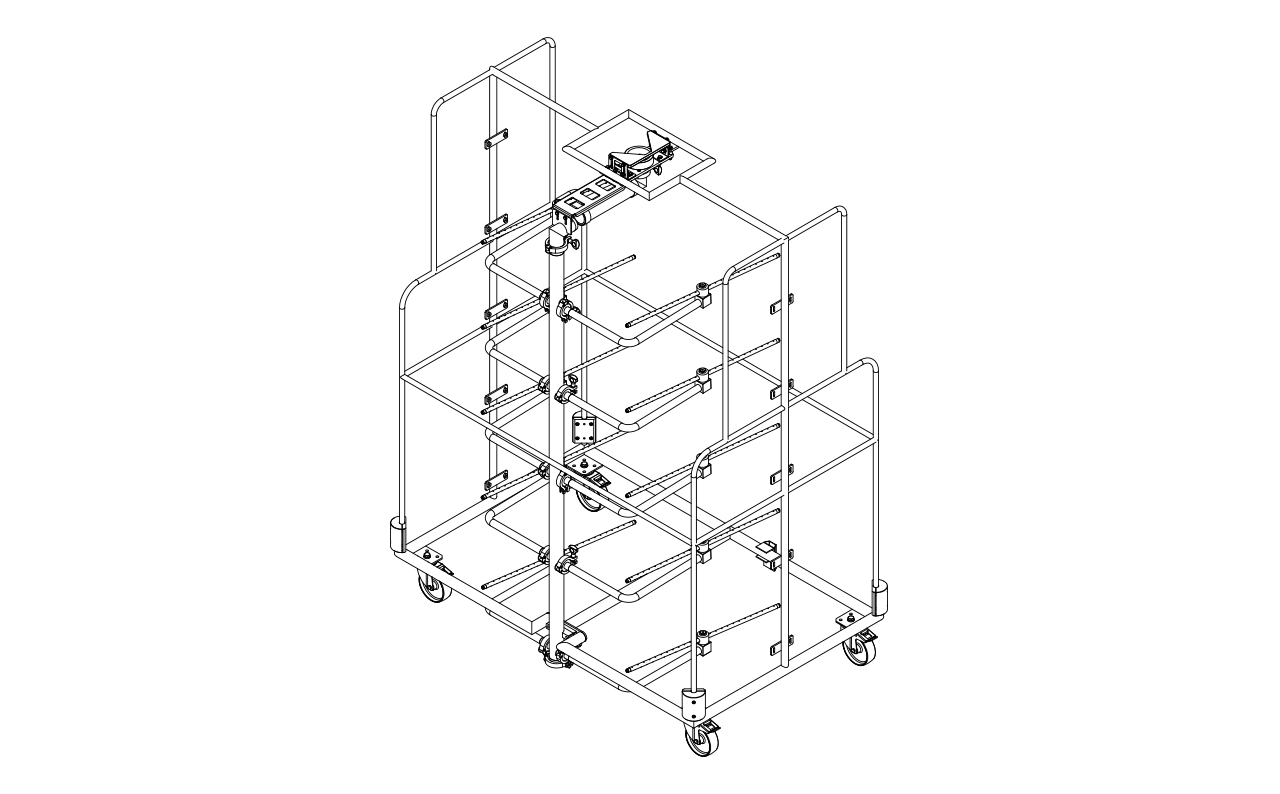

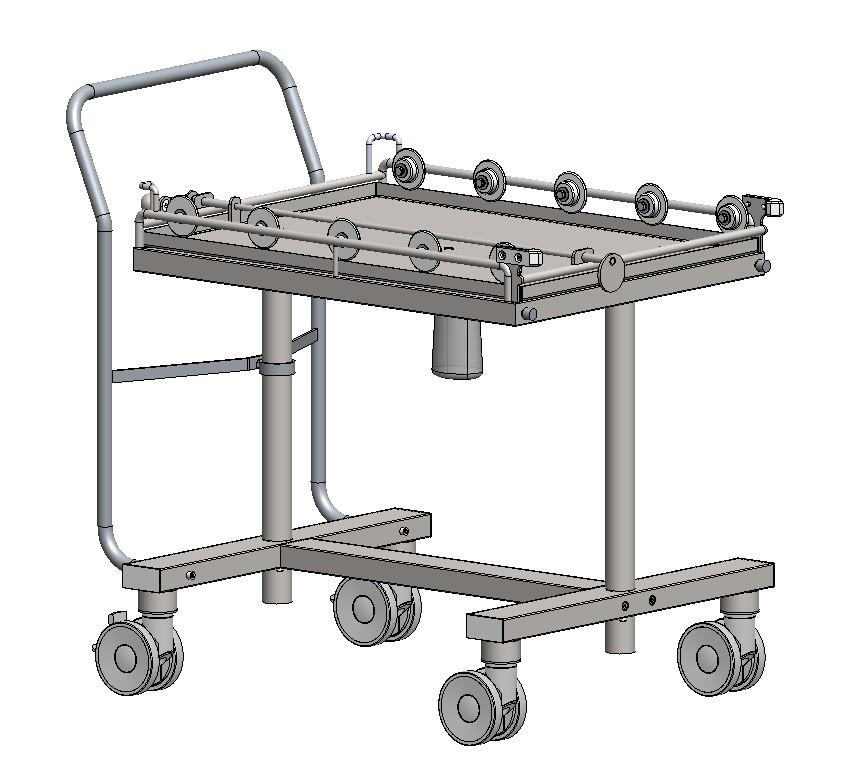

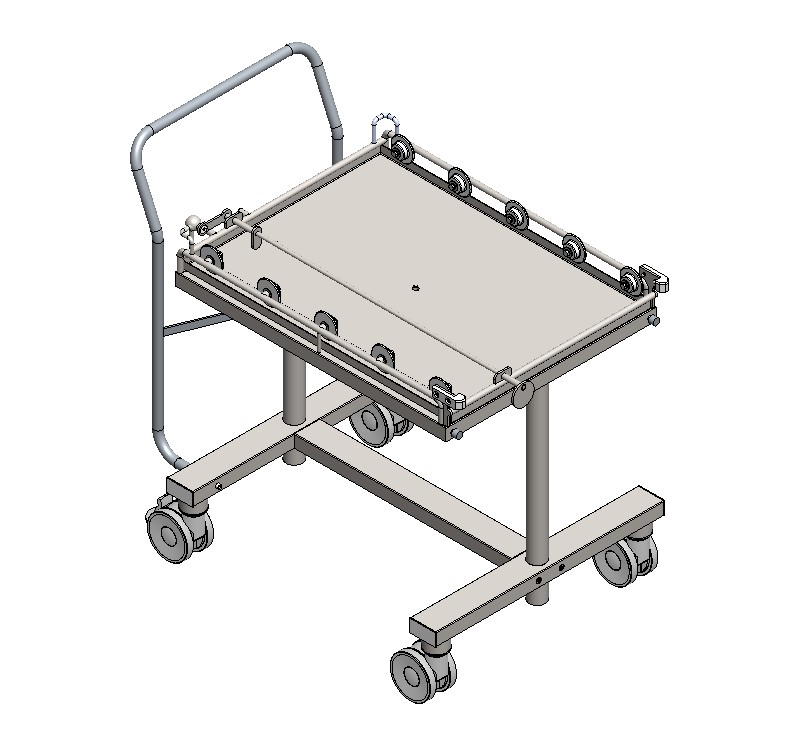

A wide choice of loading accessories is available to customize the machine according to different customer needs: internal and external trolleys, variable height trolleys and washing baskets.

A full range of kits for specific cycles, and baskets suitable for washing all surgical instruments and common equipment in use inside CSSDs.

Within the hospital sterilisation process, the thermal or chemical disinfection phase is absolutely essential. Reducing the risk of hospital infection contributes to the safety of the healthcare staff handling the medical device during its packaging at the CSSD prior to the sterilisation process. The process controls and prevents contact with contaminated devices, removes blood, saliva, tissue and residues that may form a barrier during the sterilisation process, and reduces the microbial load prior to the packaging and sterilisation process, safeguarding the safety of personnel working in the clean area of the CSSD.

Thanks to the RJ45 connection port, data transmission to advanced external tracking systems such as Cisa TRACECARE® is possible.

Tracecare® is the traceability system developed by Cisa Group, which in its full version makes it possible to manage and monitor the kits’ process through the different areas (dirty area, clean area, sterile area) that make up the CSSD, helping to reduce clinical risk.

Cisa Group’s washing and disinfection systems are Class IIB Certified Medical Devices complying with 93/42/EC and compliant with the following directives and laws, product standards and quality systems. The P84 undercounter washer disinfector, also a Medical Device, is Class IIB.