Cisa Group develops high-temperature steam sterilisation technologies to meet all operational requirements, in accordance with current regulations and the production capacities of hospitals, clinics and medical facilities of all sizes.

For over 75 years, Cisa Group has been a world leader in steam sterilisation processes for sanitary infection control in hospitals.

For over 75 years, Cisa Group has been a world leader in steam sterilisation processes for sanitary infection control in hospitals

Expertise in healthcare sterilisation has resulted in an innovative medical waste sterilisation system that exploits the potential of saturated steam.

Life Science sterilisation, specific technologies for laboratories and research centres to process laboratory glassware, accessories and cages, and for animal research facilieties.

Cisa Healthcare‘s healthcare and hospital sterilisation systems are medical devices that are used in the CSSD areas of hospitals for high temperature sterilisation of medical devices in accordance with regulations and certified procedures.

Reusable medical devices (RMD) and surgical instruments used in hospitals, as well as other items generally used in healthcare, are constantly reprocessed with high-temperature steam sterilisation.CSSD (rif. Dir. EU 93/42 sui DM).

Inside the CSSD, Cisa Healthcare’s sterilisation systems are positioned in the clean area with pass-through access to the sterile area, usually via pass box systems (pass-through windows).

Sterilisation plays a key role in the prevention and control process of hospital infections or healthcare-associated infections (HAI).

The CSSD (or Hospital Central Service) is the department where medical and surgical supplies and equipment, both sterile and non-sterile, are cleaned, prepared, processed – sterilised – and then stored, preserved and returned to the wards for patient care and surgery.

Hospital sterilisation is a process that results in the (almost) complete destruction of any microbial form, i.e. the elimination of all pathogenic microorganisms from the treated surface.

The steriliser uses saturated steam with an operating temperature range of 105°C to 140°C and an operating pressure of up to 2.6 bar, in accordance with the current regulatory standards applied within the CSSD (ref. EU Dir. 93/42 on MD).

The sterilisation of surgical instruments is one of the most important steps in the process of controlling the spread of infections in healthcare (healthcare-associated infections – HAI).

A material, an object, or a reusable medical device such as a surgical instrument, is considered sterile if the Sterility Assurance Level (SAL) is less than 10-6; that is, when the probability of a microorganism being present on its surface is less than one in a million.

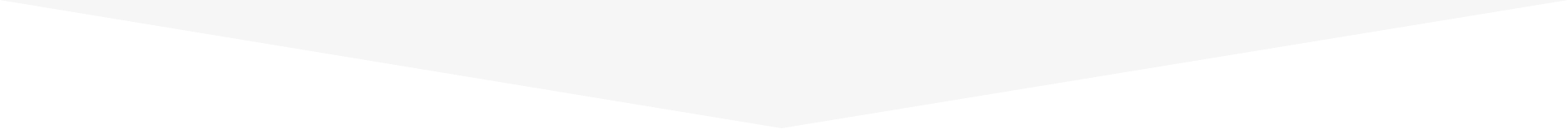

The range includes small and compact benchtop autoclaves for high-temperature sterilisation in low production capacity healthcare environments, and flexible freestanding saturated steam autoclaves of all sizes to complete high production capacity hospital projects and CSSDs.

Each series is designed to optimally handle the reprocessing associated with different medical applications and to meet the sterilisation process regulations and the varying operational needs of healthcare professionals, clinical engineering and hospitals.

Benchtop

sterilisation

system

< 1 US*

From 18 to 75 liters

Small capacity

saturated steam

sterilisation system

From 1 to 3 US*

From 70 to 218 liters

Medium capacity high-temperature saturated steam sterilisation system

4 ISO*

255 liters

From 4 to 12 US*

From 313 to 868 liters

High capacity

high-temperature steam

sterilisation system

From 28 to 56 DIN

2790 -5250- 5580 liters

The 23 litre table top is the best value in its class.

The machine can be directly connected to a PC via a USB port on the rear, and also has a printer integrated in the control panel to record and store paper reports of each sterilisation cycle.

Small steam steriliser complying with the latest regulatory and technical standards, compliant with UNI EN ISO 13060 Class B and PED 2014/68/EU for the reprocessing of surgical instruments, gloves and rubber materials and the treatment of liquids in open containers, empty glassware, flasks, test tubes, pipettes and Petri dishes.

With its 77 litre chamber capacity, the P-290 is an ideal benchtop autoclave for healthcare facilities that require high productivity and maximum reliability. It is equipped with an autonomous chamber heating system by means of an electrically operated steam generator; it is complete with a pressure switch and pressure transducer to control the pressure and temperature inside the chamber. Vacuum is achieved by means of liquid ring pumps.

The small production capacity Cisa Healthcare P-3000H and P-3600H Series autoclaves are ideal for clinics and healthcare environments with an operating room where maximum efficiency is required in a limited space.

They are the right answer for facilities handling around 2000 to 2500 operations per year.

Their optimised dimensions also make them ideal for the completion of large CSSD projects, where they can be combined with even more powerful technologies to achieve the desired production targets.

MODELS:

CISA P-3270 H

THE SMALL ONE IN THE RANGE, MADE JUST LIKE THE LARGE ONES

CISA P-3670 H

THE NARROWEST 2 SU ON THE MARKET

CISA P-3690 H

DEPTH LOADING WITHOUT SIDE ACCESS

The Cisa P-3270 H Mini is equipped with a single door and has a circular sterilisation chamber that ensures excellent temperature distribution and a lightweight design. It allows the treatment of 1 SU with a fast cycle of less than half an hour.

The P-420H and P640H series of medium production capacity saturated steam sterilisers for healthcare applications are stand-alone models ideal for clinics, healthcare environments and hospitals with a relatively high volume of operations.

Due to their medium to high capacity, these models are very often used in the design of CSSDs and central sterilisation services in hospitals.

Cisa’s medium capacity steam sterilisers are able to handle the reprocessing of RMDs generated by an average of 2 operating theatres (3,400 operations per year), getting to handle – with maximum capacity equipment of 12SU – up to 6 operating theatres (over 10 thousand operations per year).

It is possible to choose from a wide and versatile range of steam sterilisers with capacities ranging from 4 to 12 sterilisation units (and chamber volumes ranging from 255 to 868 litres).

Available in single door or double pass-through door versions, the wide range of models with different overall dimensions makes it possible to respond effectively to all customer requirements and to easily integrate the equipment itself into even the most complex projects.

The P-420 is an ideal freestanding solution in CSSDs and other areas dedicated to professional high-temperature steam reprocessing.

The P-640H is available in three different sizes, to design your spaces in the best possible way: the Standard version is 1175 cm wide, the Slim version is only 903 cm wide and the Large version is 1424 cm wide. It is also possible to request the chamber on the right or left side and manage the technical module and maintenance access accordingly.

JUST 1175 WIDE

The Cisa P-1000H Series of large sterilisation autoclaves is the perfect solution for hospitals and CSSDs that require high production capacity.

These sterilisers range from 12 to 18 sterilisation units and are capable of meeting the reprocessing needs of at least 9 operating theatres handling more than 15 thousand operations per year.

The P-1000H Series equipment is available with a single door or with a horizontally sliding double pass-through door. It is possible to install these models flush with the floor by providing an ad hoc pit and specific loading accessories. The external trolley enters the chamber, which allows for an optimised supply of loading accessories.

The P-1000H series, with the same loading capacity as the P-640H, has half the depth of the P-640H, and this ensures ergonomics suited to the required high productivity by reducing the number of loads (by operators) and the number of cycles (of the machine).

CISA P-1113H, P-1115H, P-1120H

961-1182-1478 Litri | 12-18 US

The Cisa P-H hospital sterilisation autoclaves can be configured with different operating modes for steam generation to meet the many needs of the customer and the characteristics of the healthcare facility.

Cisa Group sterilisers are equipped with a mechanical air extraction system consisting of a liquid ring vacuum pump that guarantees maximum speed during the conditioning phase and efficient drying in the post-sterilisation phase.

Alternatively, the

option can be installed. Cisa Group’s patented AQUAZERO® system doesn’t require the use of water for vacuum generation and is therefore the solution for a sustainable sterilisation process that can save up to 400 litres of water per cycle.

The sterilizers are supplied with

The RJ45 connection port allows data transmission to advanced external tracking systems such as Cisa TRACECARE® is possible.

Tracecare® is the traceability system developed by Cisa Group which, in its full version, allows the management and monitoring of the kits’ process through the different areas (dirty area, clean area, sterile area) that make up the CSSD, helping to reduce clinical risk.

High reliability and durability |

|

Shorter cycles |

|

Compact design |

|

Easy to operate |

|

Eco-friendly technologies |

|

Highly customisable |

To suit your industry, your operational requirements & your site requirements |

A wide range of loading accessories is available, made of AISI 304 steel and designed to customise the machine according to the different needs of the customer. They are also available with variable height and automatic loading/unloading devices designed for manual loading options such as internal loading trolleys with removable and adjustable shelves, or loading platforms and grids to make it easier for the operator to position the material inside the sterilisation chamber and retrieve it after the sterilisation process.

Loading.

Automatic loading and unloading devices with the use of a platform are designed to move the steriliser trolleys automatically. This function speeds up the loading process and frees the operator, who can remotely monitor the progress of the cycle (thanks to colour indicators), and carry out other activities within the CSSD.

It is possible to integrate the automatic loading and unloading system with a trolley return device (pass-through hatches) that allows the trolleys to be manoeuvred on the platform from the sterile area to the clean area of the CSSD in semi-automatic mode.

Cisa Group can supply the customer with classic stainless steel sterilisation containers in standard sizes.

The Cisa Group Sterilizers systems are in compliance with the following directives and laws, product manufactured under a quality system.